Gold plating is a decorative technique and one of the commonly used terms. Initially, it referred to coating the surface of objects with a thin layer of gold. Later on, with the arrival of the new century. The use of gold plating on product surfaces is becoming increasingly frequent

Until now, with the innovation and development of the market, the increasingly frequent use of electroplating gold, electroplating gold can reduce contact resistance, improve conductivity, make products easy to solder, have strong corrosion resistance, and have a certain degree of wear resistance (referring to hard gold). Therefore, it has a wide range of applications in connectors, precision instruments and meters, printed circuit boards, integrated circuits, and other areas, such as Pogo pins.

Pogo pin is a type of Pogo pin that is formed by assembling, riveting, and pre pressing three basic components of a needle shaft, spring, and needle tube through precision instruments, and can compress and power on. It replaces various old versions of AC/DC power supplies, micro USB, computer adapters, audio plugs, RJ45, and other functions on the market, and achieves waterproof, safe, convenient, and directional charging (forward and reverse charging).

Most of the current in the Pogo pin is connected through male and female connections, allowing the Pogo pin to compress and conduct electricity. During product use, the elasticity, impedance, and compression of the spring play a major role, such as immature technology, or the internal friction and impedance of the spring structure, making it unable to compress properly and ultimately unable to achieve the product's function.

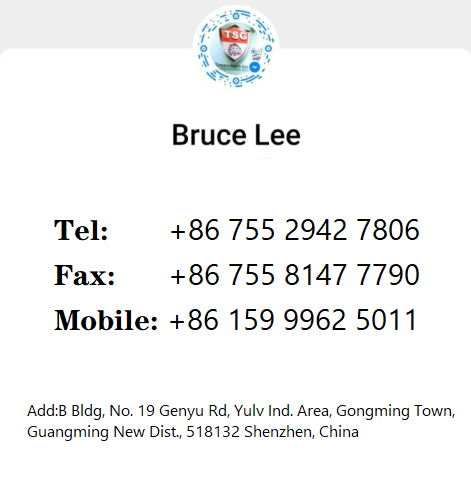

At LinkWise Technology, Pogo pins are leading domestic research and development, sales, and mature Pogo pins that can achieve various structural processes. They are also mass-produced and shipped to various parts of the world.

Electroplating gold on the surface of pogo pins can directly affect the quality, reliability, and appearance of a product.

For example, quality: The pogo pin undergoes bottom layer nickel plating and surface gold plating treatment on the needle shaft, spring, needle tube surface, and inner wall of the components! So Pogo pins can make the product safer during use, without causing safety accidents such as heat generation, deformation, combustion, or fire during long-term use, and without being unable to function due to a small Pogo pin, affecting the entire product's inability to use.

For example, reliability: The pogo pin undergoes bottom layer nickel plating and internal gold plating treatment on the surface and inner wall of the component needle shaft, spring, needle tube! So Pogo pins will have better reliability during use, such as current, elasticity, impedance, lifespan, and oxidation resistance.

For example, aesthetics: Pogo pins are gold-plated on the surface of the product's appearance! Assemble to the entire set of watches, bracelets, glasses, medical products, and more! Due to its small size and luxurious gold color, it brings customers a visual impact of high-end, atmospheric, upscale, low-key luxury, and meaningful products.

LinkWise Technology focuses on the high-end pogo pin market, provides technical solutions, and takes it as its responsibility to provide customers with high-quality products.